Most people have fond memories of the toys they used to play with while they were young. Some of you may have had a stuffed bunny rabbit or a robot that obeyed simple commands as your favorite toy. However, making a toy is much more complicated than playing with one. Making a toy requires skilled factory workers, lots of raw materials, and sophisticated machines. A toy factory is a busy place where many activities like molding, painting, and final packaging of the toys are going on simultaneously.

4 Things You Come Across When You Visit A Toy Making Factory

Raw Materials That Are Used To Make A Toy

Earlier toys were made of materials like wood and clay. However, in the present time, most toys are made up of different types of plastic. To own a toy factory, you must know the difference between thermoplastic and thermosetting plastic. Toys that can be recycled are made of thermosetting plastics like Polythene, Polycarbonate, Acrylic, and PVC. These plastics can melt if heated to a sudden temperature after polymerization.

Thermoplastic production is both cost and energy efficient. Thermoplastics do not get discolored even if they come in contact with common industrial solvents. However, the quality of thermoplastics may deteriorate even if exposed to the Sun rays for long periods.

Thermosetting plastics like Melamine and Polyurethane remain solid and do not melt once polymerized. Thus one key advantage of thermosetting plastic is that they are highly durable. Therefore thermoplastics are used to make environmentally friendly recyclable toys, and thermosetting plastics make toys that people would like to keep for a long time.

Moreover, thermosetting plastics are good insulators of electricity. These plastics do not get corroded easily and are available in various colors, making them perfect candidates for the toy industry.

Usually, toys like miniature action figures or cartoon characters use thermosetting plastics. Toys like Lego blocks use thermoplastics. Although plastic is the most extensively used raw material for making toys, other materials like metals or wood are also used in small quantities.

Metal like lead and alloys like steel go into making miniature bikes and cars. However, in a toy-making unit, metals are mainly seen in wires and die casts used to mold plastics into various shapes and sizes.

The Machinery That Is Used In The Production Of Toys

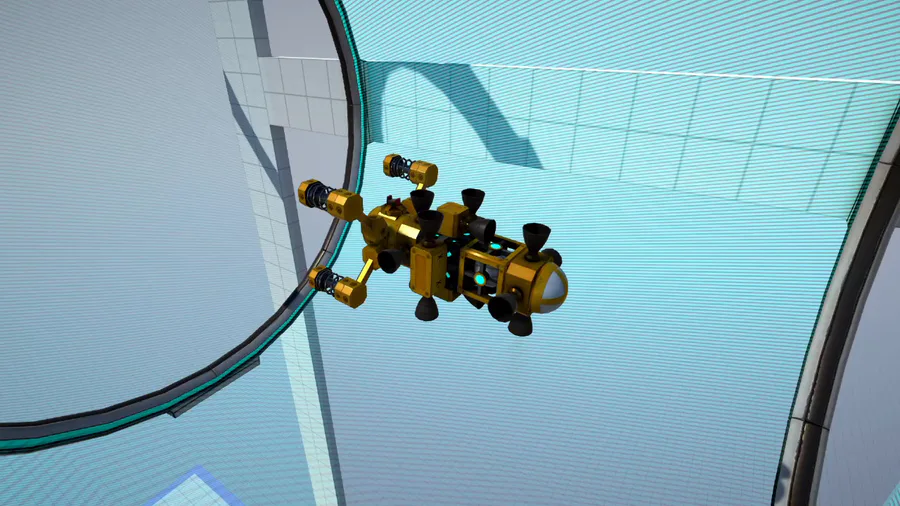

A molding machine is the main equipment you will come across in a toy-making unit. The method used for molding might vary; some objects require blow molding while others require injection molding. In the case of injection molding, molten plastic pellets pass on to a mold. The mold helps create the final three-dimensional toy.

Since injection molding machines cost a lot, toy factories take adequate security measures. An Indian webcam can be installed to help monitor a toy unit's activities even after the workers have left.

Toy Painting Unit

Most toys need painting to produce the final product. In traditional toy-making units, simple hand wooden or clay toys were painted by artists using simple brushes. In the present times, airbrushes paint toys.

Since paints contain lead, workers need to be careful while using them. High levels of exposure to heavy metals like lead can cause several ailments and can even lead to death.

Hence workers are given masks and gloves when handling lead-containing paints.

A Toy Packaging Unit

A toy factory has a packaging unit to pack the toys after the final product is ready. A packaging unit usually follows an assembly line where different people perform a small task component. If the first person puts the toy in a plastic package, the next person puts it in a cardboard box, followed by a third person who finally seals the boxes.

Since the final packaging has to be neat, workers usually wear vinyl gloves while packaging toys. Toy factory owners usually contact a vinyl gloves powder free factory near their unit to supply gloves. The main advantage of powder-free gloves is that they do not cause allergies. So workers can wear them when they are working for long hours.

Moreover, vinyl gloves are soft and comfortable to wear. The latest advances in producing these gloves have considerably enhanced their strength and flexibility.

Conclusion

A visit to a toy-making unit can be a fascinating experience. A modern toy factory has large machines, conveyor belts, and even robotic arms, which help production. The toy-making industry is a multi-million dollar industry with giant players in the global market competing with each other.

If a person is interested in opening a toy-making unit, he has to first create a product that will spur great demand in the market. After a unique product is made, a prospective toy factory owner will have to undertake a long journey. He will have to select a site for the factory. After a factory site is selected, machine procurement, worker recruitment, etc., will keep a prospective toy owner busy for a long time.

0 comments